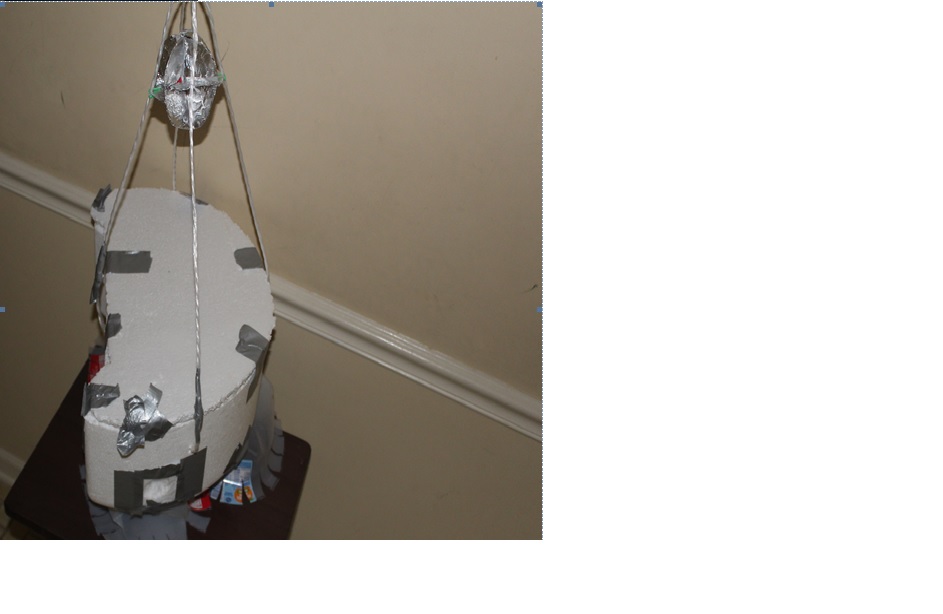

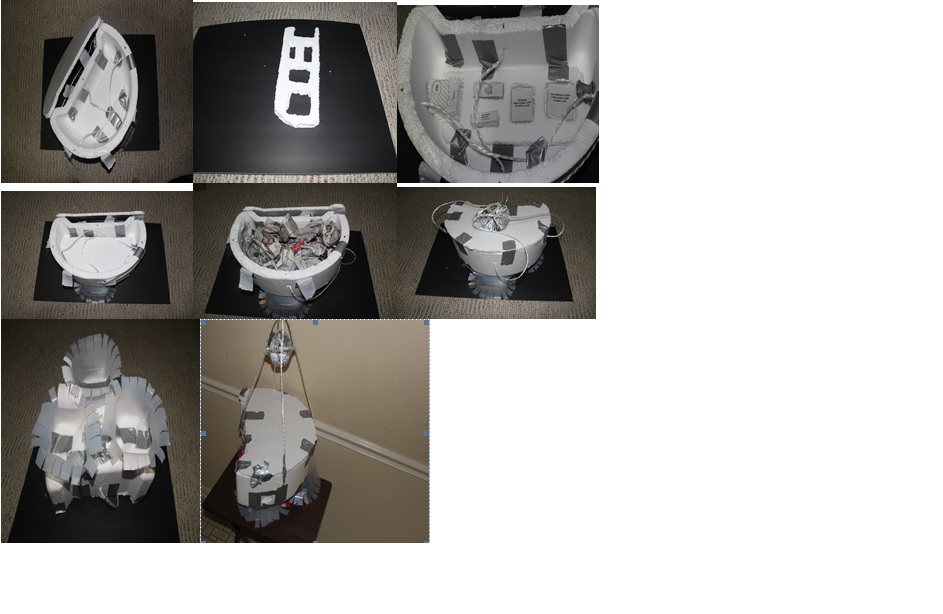

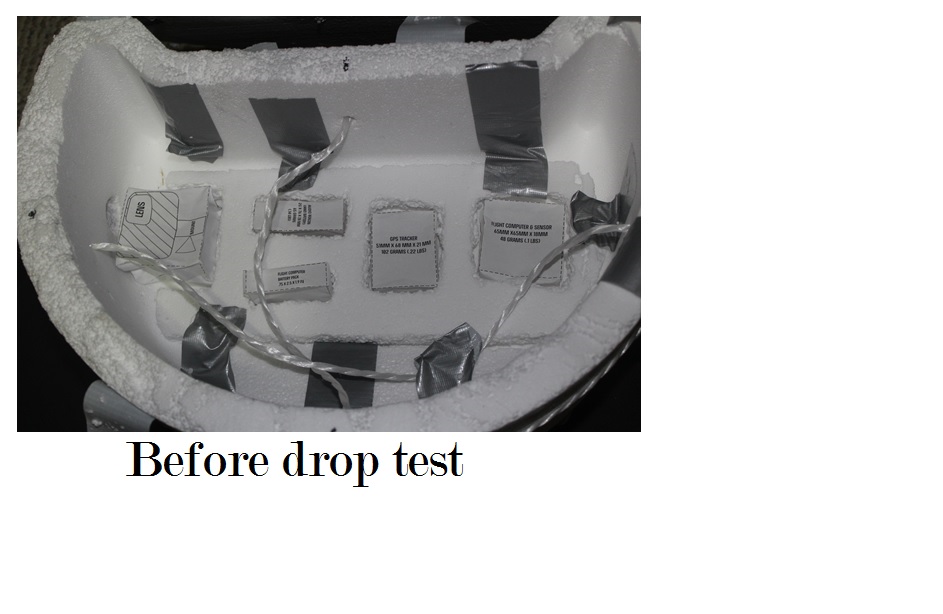

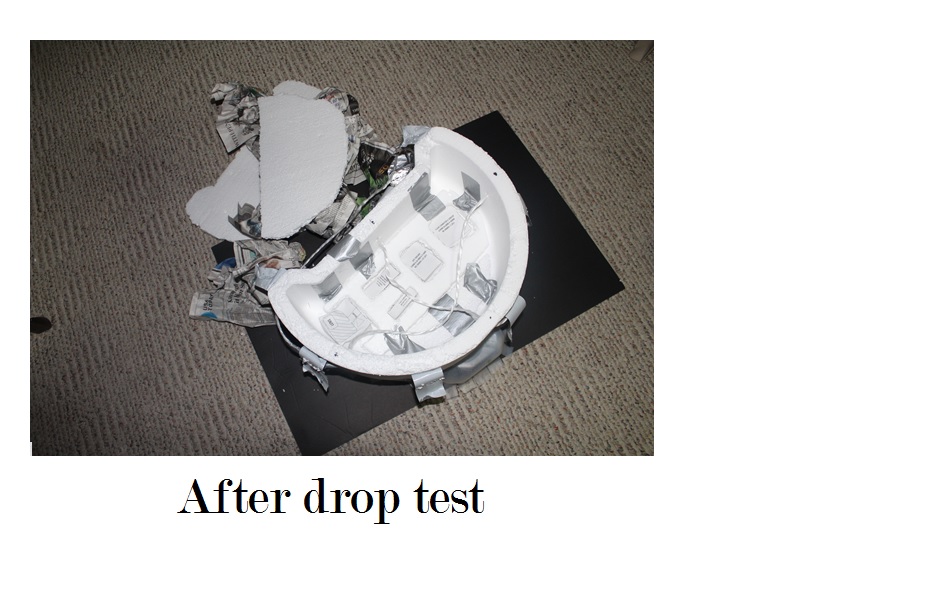

We have used Styrofoam (Semicircular oval shaped container that came with our microwave packing) as our container to keep all the mock components. We cut a piece of thermocol to set within it and designed it to have gaps to keep each component in it .We had made a hole at camera location so that camera can take photos on flight .For further protection we covered the components with another piece of thermocol and then again covered it with crumbled newspaper and finally covered it with thermocol lid sealed with duct tape . We used Styrofoam as our base as it gives temperature protection to our equipment. Further for smooth landing we attached half cut gallon milk bottles to the base .We made several cuts at the bottle end and curved it at bottom to give smooth landing .Also we attached a radar reflector on top of the string used to hold payload .It is made of cardboard and covered with used aluminum foil .It is used for air traffic control .Also radar is attached to the string so that it helps to stop the spinning of payload during flight .Since all materials are lightweight the overall weight(including the mock components containing pennies ) is less than 3 pounds .We chose the oval shaped design so that it moves in direction of wind and doesn’t spin around in space .All the materials used to make payload are recycled materials .Our drop test was successful and all components were safe after landing .Data visualization is given in attached photographs.

Contact us

Thank you for your interest in contacting Future Engineers. We look forward to connecting with you!

General Inquiries

support@futureengineers.orgSponsorship Inquiries

sponsor@futureengineers.org